In my previous lab, I had a small (27U) rolling rack at the side of my desk. When it finally got its shape, I started to move to my new lab. The equipment removed the rack disassembled.

I was a bit depressed on this as I had the feeling I'll never be able to put this together once again.

As I was reading things on the Facebook, I seen a guy trying to sell a whole bunch of outdated Cisco networking equipment. Nobody was interested, there came ugly comments on it, to throw the whole thing to the trash.

I seen a potential on something. Those Cisco units were installed into rack. So I wrote to him, if the rack containing the switches are on sale.

So I've two Rittal 42U height 600x800 racks for $100 each. I had some cleaning, metal work and paint repair with it (full repaint wasn't required, it has almost no rust just some dirt). One set of the vertical rails are not compatible, one rail mount was missing. Also I wanted open frame rack, so removed all of the doors, side panels, back panels.

Also I wanted to be able to move it on some rollers, but not every direction, just strictly need to pull out from the wall to be able to access the back. So I made legs with bearings as rollers.

In the last week finally put back most of the equipment to it (some not fit, it will be go into the other rack when I'll able to find time to rebuild the back vertical rails.

One of my problems with the rack, how to access the equipment connectors on the back, from the front of the rack. I wanted something modular to be able to put various type of connectors to it.

Built a 1,5U unit onto the top of the previous rack from aluminum extrusion a 3D print. It failed. Wasn't precise enough, won't fit things I wanted to put in.

I was thinking about some Panduit modular patch panels, but never bought it. So just left it.

I put this thing to a side for years.

It has two issues for me: It is not on sale in Europe, it uses imperial screws what isn't easy to source here.

I designed and built a 3D printed 3U height modular front panel. It can accommodate 16 modules. It is great, I put it into the rack already, with the breakouts of the four channel HP 6627A power supply.

This could be the final solution, but...

...when it was already built just realized, there exists something called Eurorack Modular Synths. It perfectly match with my ideas. I bought two set of rails.

The 19" rack mount was not included, but by surprise, the original endpieces are already 3D printed

The plan is to design a new endpiece with rack ears.

In the first rack, I'll keep my original design, but in the further rack or racks I'll switch to EuroRack.

In the last few years I was mainly working with Kubernetes. For this I previously built a K3S cluster from 5 Pine A64 SBCs. It broke down (dead SD cards), but I intend to rebuild it.

I thought, it would be a great idea to put these units into the modular front panel. Designed a holder for it.

Didn't print it when the design was ready as my printer had issues, later I didn't find time for it.

To be honest, I done not too much in my electronics project during the summer. The PCBWay asked, if I have problems - absolutely not - and suggested why I don't try out their 3D printing and CNC machining capability.

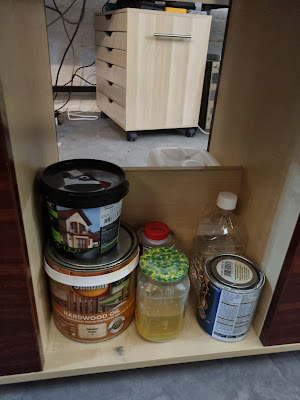

I was thinking this is a perfect opportunity for this. Made a quotation to this in PETG and some small part in resin. I can tell you, I was shocked. Mainly in the resin prices.

If the things I'm trying to print with a resin printer coming on these prices, absolutely nothing justify keeping my resin printer in the future.

Now the quotation is on. I'll write about the experience and my further way in 3D printing when the printed parts arrive into my hands for inspection.